Quick Install Tips for Diaphragm Pumps

This article will cover how to avoid common installation mistakes with three easy steps:

What is an air-operated diaphragm pump?

Air-operated double diaphragm pumps (AODD) are used to transfer oil, gas, paint, ink coatings, wastewater, and the detergents and cleaners used in car wash applications. The Graco Husky AODD pumps can handle:

- Waxes and soaps

- Rinse chemicals

- Aggressive alkaline pre-soak detergents

- Tire cleaners

- White wall cleaners

- Engine cleaners

To achieve top performance from AODD pumps, they must be installed correctly. The 3 easy tips in this article will help you get maximum pump performance.

Tip #1: Checking inlet airline size and pressure

Inlet air pressure plays a key role in getting the most out of your pump. Diaphragm pumps operate on a 1-to-1 ratio, meaning the pressure of the inlet air feeding the pump is directly related to the fluid pressure at the pump’s outlet.

Example: If the target outlet pressure of a 1-inch, 50 gallon-per-minute (gpm) pump is 100 pounds per square inch (psi), the inlet air pressure entering the pump’s air valve must be greater than or equal to 100 psi.

The appropriate airline size for a pump is located in the manufacturer’s installation and operation manual. As a general guideline for AODD inlet airline sizes, match the airline hose size to the air inlet port size on the air valve. If you use an airline that is too small, it will starve the pump of the fuel – compressed air – it needs to operate at top performance. Upgrading to a larger airline is an easy fix that only takes a few minutes to complete.

The most common mistake users make when installing an AODD pump is that they install an airline that is too small. Installing the correct airline size with an air regulator will solve the most common installation problem.

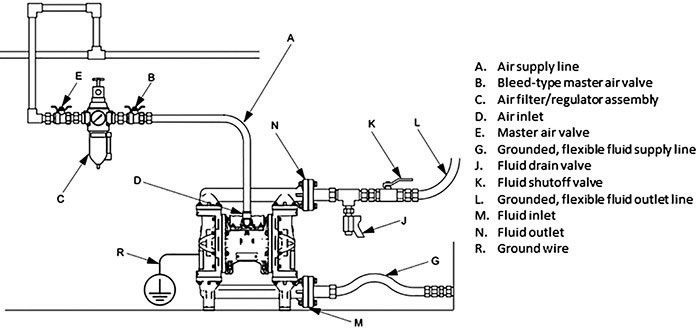

Too little system back pressure may cause the pump to run inefficiently because the ball checks may not check as quickly. Too much back pressure can cause the pump to stall if the fluid pressure overcomes the air pressure to the pump. To control the flow and pressure of an AODD pump, install an air regulator assembly (see C. in the diagram below) to control the incoming air pressure.

Tip #2: Inspecting muffler icing and restrictions

Mufflers are recommended during installation, since diaphragm pumps can be noisy when running at full speed. The AODD air motor requires compressed air to operate. But, when compressed air enters the air valve and channels through the pump to exhaust through the muffler, rapid temperature changes occur. At the muffler exhaust, air temperature is below freezing and can cause icing-related issues. This is bad because it decreases pump efficiency.

You might notice an icing-related issue if:

- Operation is erratic, odd, or unpredictable

- There’s visible frost on the outside of the muffler

- The inlet air has high levels of moisture

Reducing the air pressure to the pump is one of the fastest and most effective ways to reduce icing.

Here are suggested solutions to eliminate these issues:

- Lower the air pressure to the pump

- Increase the pump size to operate at lower speeds

- Exhaust air to a remote location with an exhaust port tube

- Add an airline filter with a water catcher and drain to collect condensation

- Install an airline heater to raise the exhaust air temperature above freezing

- Adjust the pressure dew point temperature with an air compressor dryer

Tip #3: Ensuring proper tubing and piping size

Here are some things the user should know about pump tubing and piping size:

- Pump inlet and outlet fluid port diameters vary based on the flow rate required

- Inlet and outlet hose sizes must match the pump’s size

- You should know the correct size at installation so you don’t need to make a modification later.

Example:If a 1-inch pump has a half-inch inlet hose connected the pump will not be able to operate at full capacity without the risk of cavitation. This risk increases dramatically as the desired fluid viscosity rises. In this example, the 1-inch pump should have a 1-inch inlet and outlet hose attached to prevent cavitation.

It is also recommended that an AODD pump be installed with a flexible inlet/outlet connection rather than being hard plumbed. As pump speed increases, vibration increases, which causes risks of loosening a hard plumb connection and leakage.

![]()